Mechanical/HVAC

A Midwestern Mechanical Powerhouse Keeps Getting Stronger

For decades, Midwest residents have seen our ubiquitous fleet of red trucks with the familiar “Evil Oval” logo proudly stating the name of our company’s largest division: “MECHANICAL.” Since 1969, Helm Mechanical has supplied expert mechanical design, engineering, installation and service to the construction industry. From construction of the smallest industrial process projects to the largest hospitals, Helm places our focus on safety, quality, and building value for our customers.

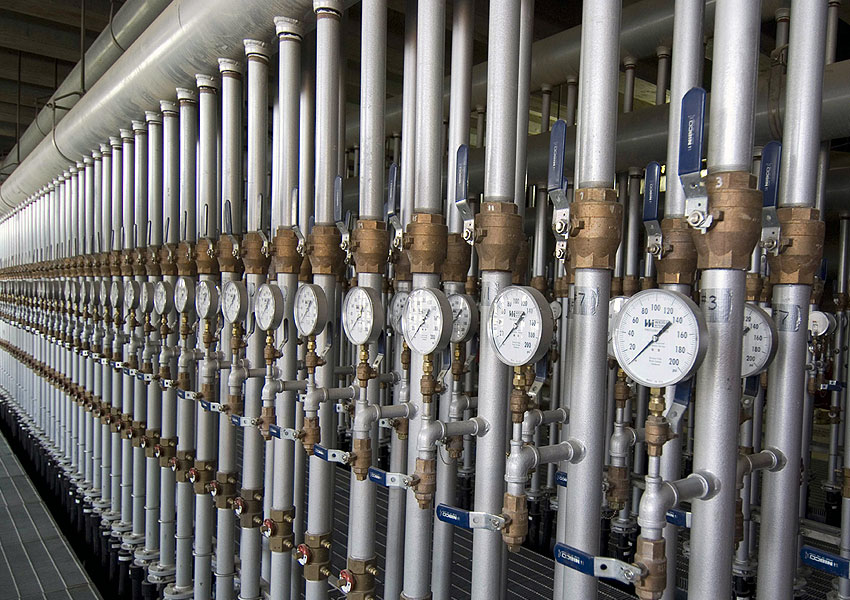

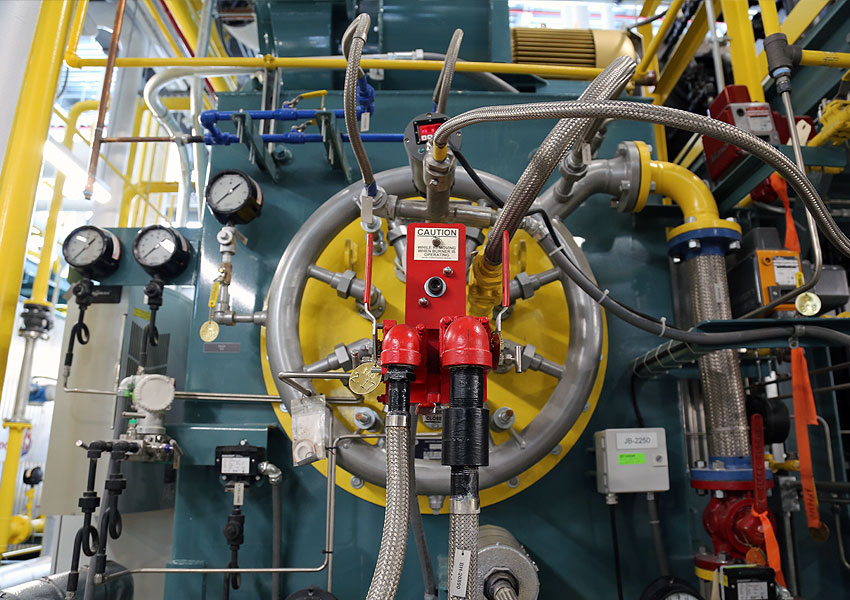

We design and install the critical operating systems that support building infrastructure and keep it operating at optimum efficiency for private and public end-users in a wide variety of markets. Our experience spans commercial, biotech, healthcare, education, agriculture, industrial processes, technology, data centers and beyond.

From the efficiency of HVAC and other piping-centric systems such as emergency power generation to manufacturing and industrial applications, our status on the forefront of technology’s bleeding edge has helped Helm forge an unmatched reputation for excellence. Technologies we not only use but have substantially helped develop for many years include VDC (virtual design and construction), BIM (building information modeling), Lean Manufacturing and HoloLens. We have served as a beta test site for many developing applications and tools and we bring our technical expertise to bear on all our mechanical jobs, small and large.

Bringing such technological firepower to market requires a high level of capitalization and commitment to infrastructure, software and talent development that some companies simply are not capable of bearing.

Our fab shops are good examples of reinvestment meeting technological strength. Helm’s Fabrication Shops are shining examples of how practical adoption of pre-fabrication technology results in efficiency and accuracy. With 160,000 square feet of fabrication, modularization and assembly shop space, the future of advanced HVAC manufacturing is alive and well at Helm today. The technological hub of Helm’s Rockford Fab Shop is the integration of our VDC and fabrication process. For more information on these processes and how they contribute to high efficiency prefabrication, please visit our Fabrication, Manufacturing & Assembly page.

As you might expect from an historic family-owned enterprise in which you will often see generations from many families working on any given project, a great deal of Helm’s success is owed to its culture. After on-boarding, new team members frequently say they’ve found a career for life. That is reflected in the collaborative spirit each our staff bring to their work at the office and in the field every day. Hallmarks of Helm’s culture include hard work, mentoring and support for others as well as sharing intelligence and our unwavering dedication to customer success.

“Helm is a very crisply run business,” said Dale Cox, a veteran of the mechanical business and Vice President. “Our leadership has real moxie. It’s quiet moxie, and that engenders trust among clients and staff alike. Businesses in our sector can be fragile, but Helm is remarkably durable. Despite its impressive growth, it still feels very much like a family business. The Helm family constantly reinvests in the company. We are sober about the decisions we make. These things attract lots of franchise players – and that’s a huge advantage. There’s an honesty about the family that you can feel at the staff level. When people come here they feel right at home. For my part, I look forward to coming to work every day. I’m not alone in that regard and that translates directly to value for the client.”

At Helm, safety is another foundational element of our culture. At the beginning of every project, our dedicated Safety VPs and their staff sit in on design and engineering meetings to ensure all processes are planned and that they proceed with safety in mind. Helm’s Safety leadership have many years of field experience. They are so good at all aspects of their jobs and have so much practical (not just academic) experience, they often propose solutions to difficult problems that not only make a project safer – but more efficient. Our EMR (Experience Modification Rate) would be the envy of any business in in our field – and it is shared across all our divisions, including Heavy, Civil and Marine – vertical markets that are considered more dangerous than mechanical. Every member of our Mechanical team, from owners to tradespeople, are on board when it comes to our commitment to safety. There’s nothing we want more than for every man and woman on every project to go home healthy every single night. To view a selection of our mechanical projects and those from other divisions, please visit our Project Explorer today. To initiate a conversation about a new Mechanical project, please click here to send us an email. We promise to get back to you promptly.

Helm’s Mechanical Solutions Include

- Design, Engineering, Construction

- Automated Pipe, Duct, and Structural Steel Fabrication and Modularization

- Virtual Design and Construction (VDC) and Building Information Modeling (BIM)

- Plumbing Systems

- Hydronic, Process, Medical Gas, and Utility Piping Systems

- Chiller & Boiler Installation and Distribution

- Air Handling Equipment and Distribution

- Test and Balance of Air and Hydronic Systems

- Commissioning

- Building Automation Systems

- Service, Maintenance, and Facility Management

- Electrical

Helm’s Defining Centers Of Excellence

- Innovation & Early Adoption Of The Finest Technology

- Enduring Commitment to Value Engineering & Lean Manufacturing

- Decades of Multi-Industry Experience Dating Back to 1969

- Highest Standards for Quality Craftsmanship

- Long-Tenured, Highly Talented Management Team

- 24/7 Service